Preventive maintenance in pharmaceutical industry is a maintenance strategy that follows the fixed schedule. Learn about its execution, scheduling and checklist

Maintenance in the pharmaceutical industry is a critical activity that influences the life, performance and productivity of an equipment. Pharma manufacturers must invest in instruments, tools, and personnel expertise for an effective maintenance strategy. There are different types of maintenance strategies, and preventive is one of them.

What is Preventive Maintenance in the pharmaceutical industry?

Preventive Maintenance is a type of maintenance performed according to a fixed schedule. It aims to prevent a breakdown in equipment by inspecting the condition of a component. if any part shows sign of defects, wear & tear and damage, even if the machine is working satisfactorily, it is immediately rectified or replaced. Preventive Maintenance in the pharmaceutical industry helps to detect problems at early stages and prevent unexpected problems, breakdowns and faults.

The schedule is set per the machine working hours or process application. Preventive Maintenance is performed when the equipment is in working condition and satisfactorily produces a desired output within the capacity.

How is Preventive Maintenance in pharmaceutical industry executed?

Since preventive Maintenance is performed on running equipment, planning the equipment for maintenance can disturb the production plan. It is necessary to plan preventive Maintenance before executing it.

Planning for Preventive Maintenance involves some steps, which are listed below

- Preventive Maintenance scheduling

- Preventive maintenance checklist

- Distributing maintenance plan to production personnel and department

- Executing the Maintenance

- Filling out the checklist and signature

Let’s discuss each step briefly

Preventive Maintenance Scheduling

Scheduling for Preventive Maintenance is a critical process for timely executing preventive Maintenance in the pharmaceutical industry. It is a centralized document for all the relevant departments and, enables production personnel to plan their production activities accordingly.

Preventive Maintenance scheduling is planning the Maintenance of individual equipment and deciding their frequency. In other words, it is the process of noting down all equipment and then deciding whether the equipment requires preventive Maintenance according to the below-mentioned time

- Every month – Monthly

- Every after two months – Bi-monthly

- Every after three months – Quarterly

- Every after six months – bi-yearly

- Or once a year – yearly

A preventive maintenance schedule is developed in tabular form, where all equipment is written in different rows. All the available frequencies are mentioned in the columns. Each equipment in row is marked with the relevant frequency

The schedule for preventive Maintenance also includes the time required for the Maintenance. It gives an idea to the production personnel about how much time the machine will be reserved for maintenance activities and will not be available for production.

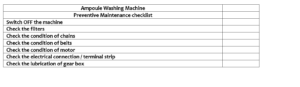

Preventive Maintenance Checklist

The checklist for preventive maintenance in pharmaceutical industry is the list of tests/checks performed during preventive maintenance. These are the detailed guidelines for maintenance personnel, about how to perform maintenance, and what components/parts of equipment need to be inspected.

The maintenance personnel should prepare checklist by keeping in mind the practical experiences, and must include all the critical parts of equipment. They can also use machine manufacturer’s guide, which manufacturer often include as a part of machine documentation, such as maintenance manual.

Format for checklist includes a tabular format, in which all the desired tests are mentioned. There is a checkbox included in front of each test. When a maintenance personnel successfully executes a particular test, that checkbox is checked, indicating a successful completion. Otherwise, it is remain empty.

At the end of checklist, a section for comment by performing personnel is included. It is used to record any particular finding during the activity.

Distributing maintenance plan to production personnel and department

When the schedule for preventive maintenance is prepared and finalized, it is sent to the production department, for their review and comment, typically at the start of the year. It is also send under special circumstances, such as if a new machine is added or changed from its current location.

The main aim of schedule distribution is to ensure that.

- All production equipment has been included in the schedule.

- It helps the production department plan their production accordingly so that the machine is available during maintenance without any production loss, by completing the production well in advance.

- Any valuable input from production personnel that would help in better execution of preventive maintenance

Executing the maintenance

When the time arrives for the maintenance of a particular piece of equipment, the maintenance department contacts the concerned production representative/supervisor / responsible for handing over the machine. The production personnel keeping in view the production activities, makes arrangement for handing over the machine to maintenance personnel.

The maintenance department prepares the resources such as tools, spare parts and oil/grease for preventive maintenance. At the given time, maintenance personnel performs preventive maintenance.

If, during the maintenance, chances are that the activity could take longer than the mentioned time, the maintenance department informs the production department well in advance. If production approves, the maintenance personnel continues the activity. Otherwise, preventive maintenance for that machine is to be reserved for another time when there is no urgency of production activity.

Filling out the checklist and signature

After the completion of preventive maintenance activity, it is necessary to complete the checklist. The person who has performed the maintenance is responsible for completing the checklist. Documentation is necessary because regulatory and standardization bodies such as the United States FDA and the ISO review them during their routine inspection. Preventive maintenance activity is inspected as a part of maintenance strategies for production equipment.

The maintenance supervisor is responsible for completing the entire documentation, in addition to maintenance activity.

After the checklist has been appropriately filled by maintenance personnel, it must be signed by production personnel and the maintenance supervisor to ensure the correct execution of the activity.