When choosing a sterilization method, there are several factors to consider, because autoclave and dry heat sterilizers use different methods. Learn about the dry heat sterilizer vs autoclave

Autoclave and Dry Heat Sterilization are two common equipment in the pharmaceutical industry, to sterilize various items in the sterile manufacturing process. They destroy harmful contaminants and kill microorganisms, which are hazardous for the final product. Additionally, their application and technology make them essential to the pharmaceutical sterile manufacturing process.

Autoclaves use steam to sterile items at high temperature and uses low temperature in the range of 100⁰C to 132⁰C. They are used to sterile stainless steel items, pharma products,s and wearables used in the pharma manufacturing process.

On the other hand, Dry Heat Sterilizer uses hot and dry air to achieve high temperatures for performing sterilization. Their typical temperatures range lies between 160⁰C to 250⁰C. They are commonly used for glassware before filling sterile drugs in them.

Autoclave and dry heat sterilizers both differ in principle, working and construction. This enables them to use it for different products and purposes. Additionally, production personnel can’t interchange their product or process. If they do, it will fail the process, and damage the product and equipment

How it helps various professionals in the pharma industry to know Dry heat sterilizer vs Autoclave

The knowledge of Dry heat sterilizer vs Autoclave is critical to any sterile manufacturing process. Knowing their differences help various professionals in the pharma industry to accurately perform their duties and responsibilities in producing quality products, and commonly include the following.

Production Personnel

It enables production personnel to plan and execute the production processes, in line with the regulatory, and safety guidelines. It also helps prevent product damage during the manufacturing process and also prevents product recall from the market. Additionally, production personnel can keep the documentation updated by maintaining a proper record of all process parameters.

Maintenance Personnel

It enables maintenance personnel to trace and troubleshoot the fault accurately. It also helps them plan different maintenance strategies, such as preventive and predictive maintenance for the autoclave and Dry Heat Sterilizer.

Quality Personnel

It helps quality personnel in developing testing methods for ensuring quality in the manufacturing process and in the end product. Additionally, quality personnel can accurately monitor the sterilization process to ensure quality during the manufacturing process.

Dry heat sterilizer vs Autoclave

Let’s look at Dry heat sterilizer vs Autoclave

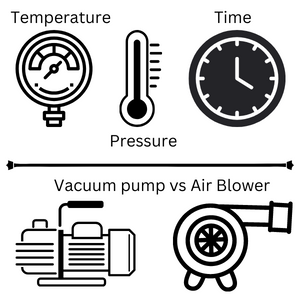

Principle of Operation

A dry heat Sterilizer uses hot and dry air to achieve sterilization temperature. It uses heaters to generate heat inside the chamber. A blower fan is used to blow and direct the air onto the heater, increasing the blowing air’s temperature. The hot air enters the chamber, where items to be sterilized are placed. The heater remains ON until the chamber’s temperature reaches the required temperature.

When the chamber’s temperature becomes equal to or greater than the sterilization temperature, heaters are turned OFF. This process repeats automatically, throughout the sterilization time, as defined by the user.

Autoclave uses steam to achieve sterilization temperature inside the chamber. Steam enters the chamber under pressurized conditions to increase its capabilities. The pressurized steam helps achieve the sterilization temperature, which would become difficult without pressure. Steam without pressure will also increase the time required to achieve the required temperature.

Temperature and pressure are individually maintained for sterilization efficiency during the sterilization process.

Sterilization Temperature

The sterilization temperature of a Dry Heat Sterilizer is higher than the autoclave and can go up to 230° C. The main reason is that DHS uses heaters to generate heat. Heaters are capable of generating high-temperature air, which is then used to increase the temperature. Pressure has no role in achieving the required temperature. This increases the limit of sterilization temperature. Additionally, there are no safety concerns involved due to pressure. Although basic safety features are essential to the dry heater sterilizer equipment.

The autoclave’s sterilization temperature is low compared to the dry heat sterilizer. Autoclave uses temperatures between 121° C and 135° C. The main reason for the low temperature is that the normal steam temperature is lower than the required temperature.

Water is converted to steam at 100° C, and steam can’t reach temperatures more than that. Pressure is created inside the chamber to enable steam to produce high temperatures. Increased chamber pressure helps steam in achieving high temperatures up to the range of 135° C. However, there is a limit to increasing the steam pressure because of safety issues and problems.

Pressure Requirement

For a Dry Heat Sterilizer, pressure is unnecessary to increase the temperature or to carry out other functions, instead, it uses heaters to increase the temperature. Since a DHS does not pressurized fluids, there is no need for safety devices related to pressure.

For autoclaves, pressure is essential and necessary for process completion. If pressurized steam is not used, it will become difficult for autoclaves to achieve higher temperatures.

For the autoclaves, it is necessary to install safety devices that prevent hazards related to pressurized conditions. Specialized safety devices are installed that automatically release steam or shut down the operation, in case of pressure malfunction.

Time Required

Dry Heat Sterilizer requires more time than autoclaves because their sterilization temperature is higher. It also requires more time to achieve the required de-contamination and killing of microorganisms.

Autoclaves require less time to achieve sterilization because they have less sterilization temperature levels. Their sterilization time is also less, as the required de-contamination can be achieved in less time

Vacuum Pump and Air Blower

The process is executed in DHS based on positive pressure displacement, and an air blower blows hot air inside the chamber. After entering the chamber, the hot air exits the chamber via the return air duct and valve.

In autoclaves, the vacuum pump is used to aid the sterilization process. It is used to execute the pre-heating and post-heating processes.